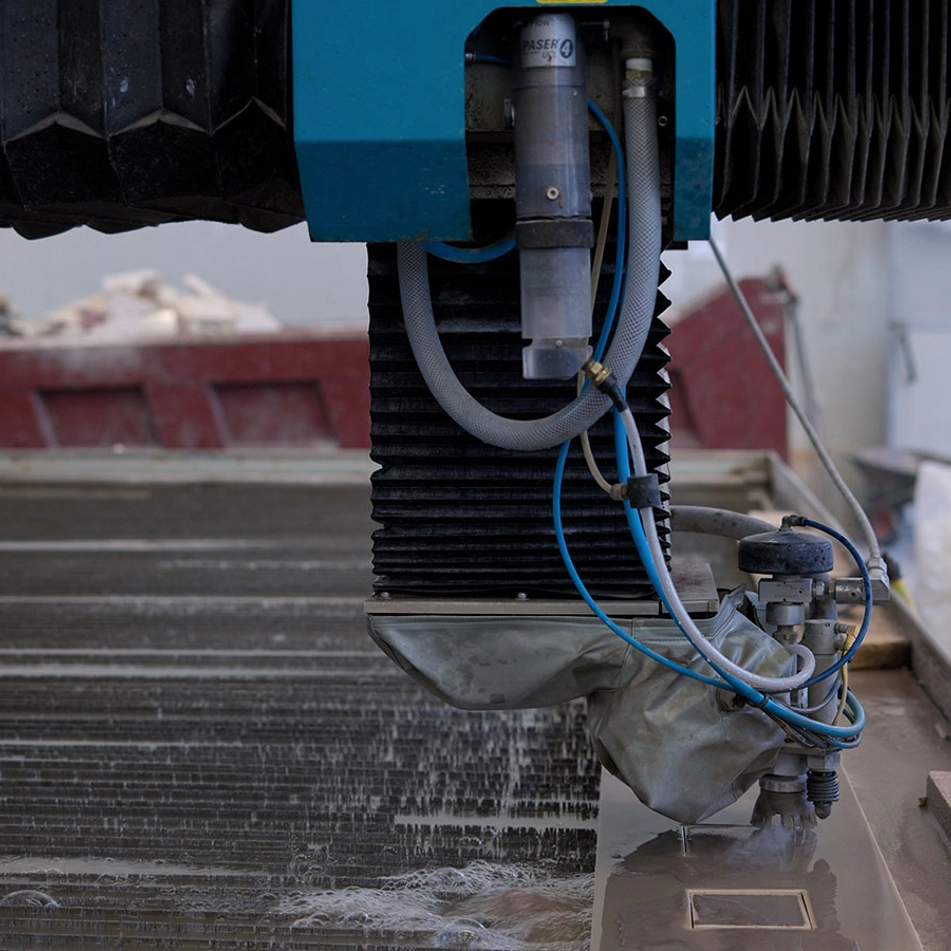

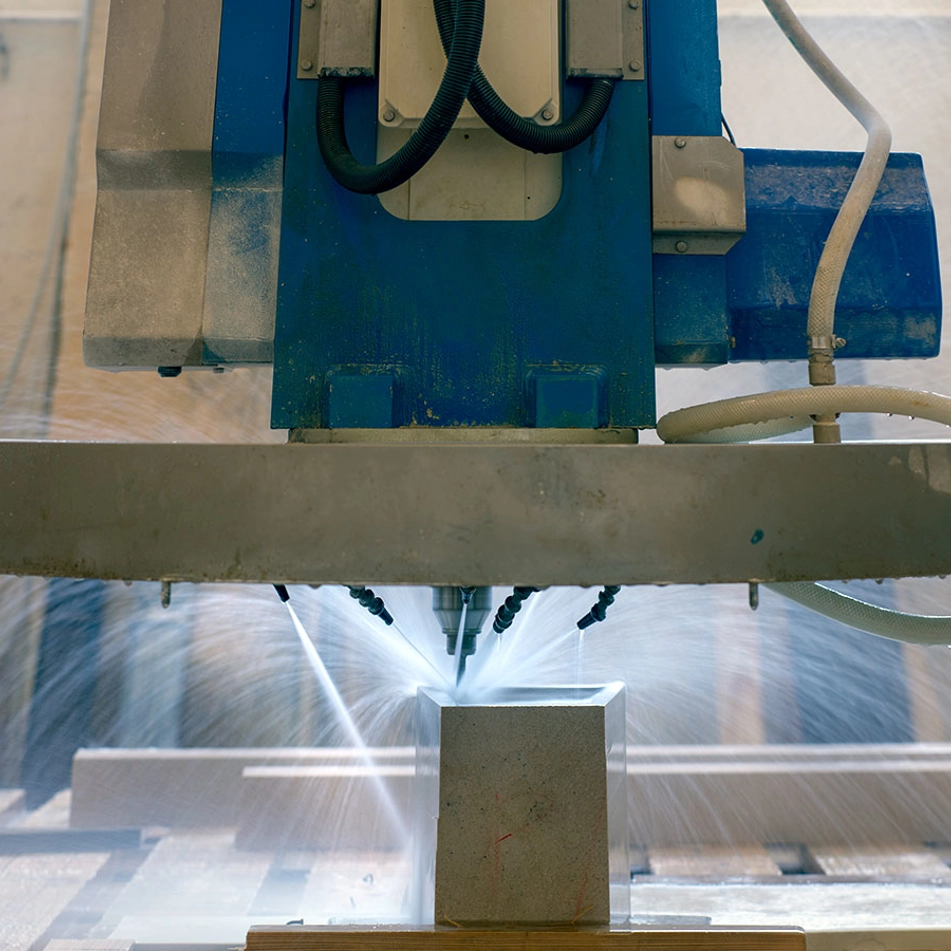

Waterjet

Waterjet is an innovative technology that uses a very high pressure water jet to cut and process materials with extraordinary precision. This machinery is particularly appreciated in the engraving, logo and lettering sectors, as it allows you to obtain results with extremely fine and precise details. The use of Waterjet reduces material waste, the versatility and efficiency of this technology make it a perfect solution for those aiming for excellence.